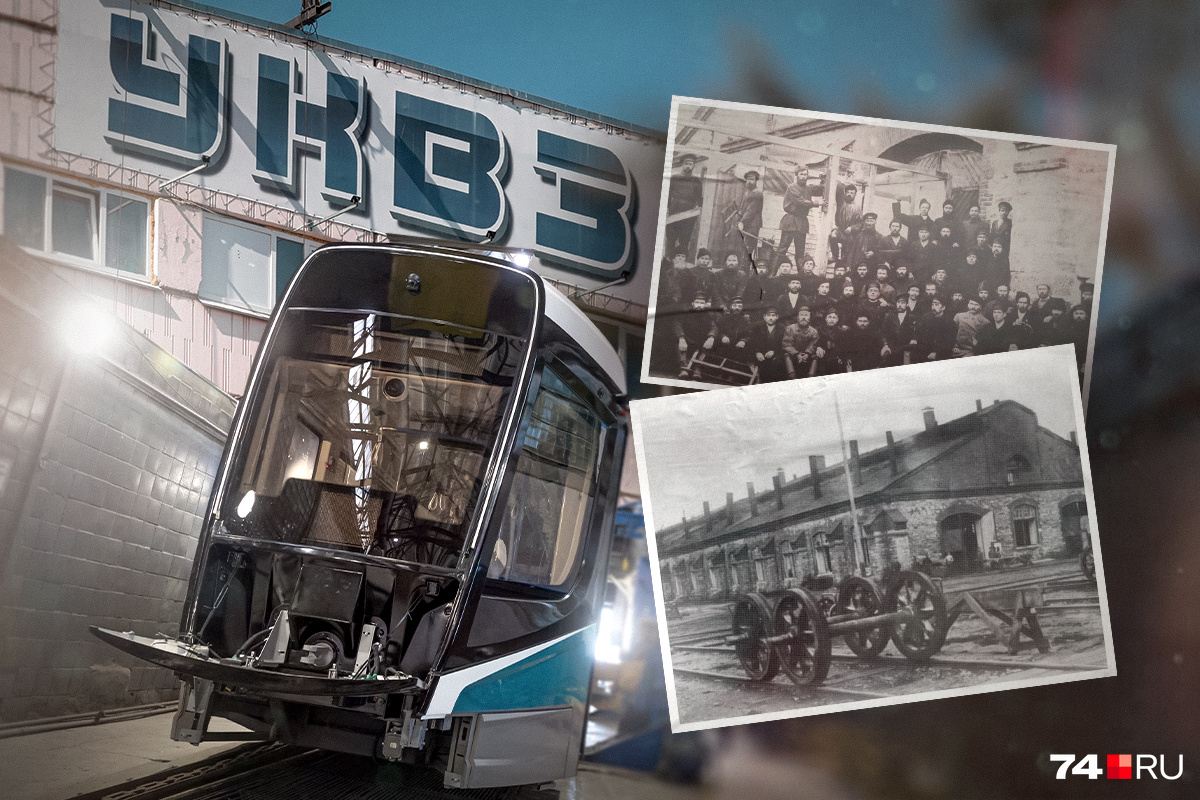

At the beginning of the last century, the metallurgical plant stood firmly on the rails and continues to move along them Source: Natalya Laptsevich, Semyon Kazmin (collage) At 7:30 the whole city wakes up to a loud whistle. The signal, just like a hundred years ago, announces the start of the working day at the largest plant in the area. At first, metal was smelted here, and then the Belgians, at the turn of the 19th and 20th centuries, re-equipped production and began producing trams. They also built the “French” bridge (not for everyone) and the “Colony” (with a luxurious house for the manager). After 1917, the foreigners left, but the company continues to operate to this day and supplies modern carriages to various cities in Russia. Our colleagues from 74.RU recall interesting facts from the history of the Ust-Katav Cabbage Plant (UKVZ) in the Chelyabinsk region and look at how the transport beloved by many was born in 90 days (spoiler: with one eye we will also see a metrotram car). Source: Mikhail Shilkin Could not stand the competition with the Demidovs Historians know about several Belgian colonies in Central Africa, but only the residents of Ust-Katav know that at the end of the 19th century another European “colony” appeared in the Chelyabinsk region. More than a hundred years ago, the Belgians rented an old ironworks and built a workers’ village across the river from it. Now it is called Pervomaika, but according to customs it is also called “Colony” – in memory of those who established the production of railway transport here. The first set of trams was delivered to the capital of Georgia, which was then called Tiflis. This was in 1901. There is no mention of Ust-Katav on Georgian websites; they are talking only about the Belgian company that built the line and supplied the trams. But the Belgians had a plant in the Urals Source: memogzauri.com Ust-Katav trams in the Tbilisi depot Source: memogzauri.com The workshops in which cars were assembled before the revolution are still preserved on the territory of the plant and are used in the modern production chain Source: Natalya Laptsevich/74.RU This building with a semicircular roof and a large window is now used as a boiler room, previously it was a production workshop; it will no longer be possible to repeat the supply of cars to modern Georgia, and this is not due to the difficult geopolitical situation. Tram and trolleybus traffic in Tbilisi was closed in 2006. But let’s return to the “Colony” of Ust-Katava. The Belgians loved a secluded lifestyle, so although they built the “French” bridge connecting the village with the rest of the city, they forbade other residents to walk on it. The “French” bridge still connects the city with the “Colony”. Today everyone can walk along it, but at first everything was not like that Source: Natalya Laptsevich / 74.RU In their “Colony”, foreigners were created comfortable living conditions, curator of the UKVZ museum Natalya Abramova told 74.RU. – 140 years. After the founding of the iron plant, it was difficult for him to compete with Demidov’s factories. Therefore, it was decided to lease it to an anonymous metallurgical company for 50 years,” explained Natalya Abramova. – Belgian specialists came to our city and founded their “Colony” on the river bank. At first, ten houses were built, including a luxurious house for the director of the plant. The village has heating and water supply systems, as well as sewerage. For the beginning of the last century it was very modern. To connect the plant and the city using the latest technology, the French Bridge was built, but only residents of the Colony were allowed to enter it. It was opened to everyone only after the revolution “Colony” (located on the left) for a long time remained the most comfortable microdistrict of Ust-Katava, looks like an ordinary village Source: Natalya Laptsevich / 74.RU Indeed, the Belgians were unable to rent the required 50 years under the contract, and after 1917 they left Ust-Katav. Moreover, “Colonia” itself, thanks to its clean air and beautiful nature, remains a prestigious area of the city. And now many plant managers live here (in the new part of the Colony), residents of Ust-Katav shared with 74.RU. The most popular tram in the world During Soviet times, the plant continued to produce trams, and this was sometimes based on house designs. After the start of the Great Patriotic War, four factories were evacuated to Ust-Katav – from Mytishchi, Leningrad, Stalingrad and Bryansk. A beautiful suspension bridge, built in 1944, was named in memory of the workers of the Bryansk Arsenal plant. During the war, the carriage plant produced artillery carriages for anti-aircraft guns and radar stations, battalion mortars, tank guns for T-34s and shells for Katyushas. Samples of military products are displayed on the territory of the plant Source: Natalya Laptsevich / 74.RU 15 years later, in 1959, the plant in Ust-Katav received the status of “tram capital of the Soviet Union.” USSR for the production of tram cars and to organize a special design bureau for tram construction at the plant. Mass production of trams began with the KTM-2 and KTP-2 models, which means “Kirov motor tram” and “Kirov trailed tram”. (During the war, the Kirov plant began to be called Kirovsky, and it remains named after Kirov to this day). But their release became a “warm-up” for the legendary KTM-5, the most popular tram in the world. They delivered it to Tbilisi, which we talked about at the beginning, and to 85 other cities of the Soviet Union. Cars with red ribbed sides are known to many citizens of the Soviet Union. Trams of the most popular model still carry passengers in Chelyabinsk and other cities. such cars. The model has become the most popular in the world, they say at UKVZ (although there are no official documents about this achievement). During peak hours, the plant employed about 5 thousand people, and the capacity of the tram assembly workshop was 750 cars per year. This workshop is still in operation, although the scope of work is more modest (but then it is impossible to remove the entire tram assembly workshop from one point; it is huge and is still in use. RU In addition to carriages, UKVZ also produced the famous Olympic bicycle. Have you ever had one? Source: Natalya Laptsevich / 74.RU After the collapse of the USSR, UKVZ began to actively cooperate with foreign companies. In 1993, the plant signed a contract with them to create a prototype of a tram car in Moscow, and the German ambassador even took it for a ride. But things didn’t go further than prototypes. turned out to be too expensive to produce, and in those days there was no money in the budgets of Russian regions to purchase it. In 1999, a modified car appeared on the streets of Moscow, on which the designers worked for several years. This happened in 2016, and in 2019 the company again. a storm struck. In February, hundreds of workers came to the gates demanding higher wages. A few days after the rally, Dmitry Rogozin, who was then the head of Roscosmos, flew to Ust-Katav. By the summer of 2019, production was loaded with orders (the rally was actually preceded by a multi-year production shutdown). Now the average salary at UKVZ JSC, according to the company, is 60 thousand rubles. Since the 1990s, UKVZ has changed its form several times. It was a federal state unitary enterprise, and in 2018 the Ust-Katav Carriage Plant joint-stock company was created. The company regularly participates in government procurement. Thus, in recent years, cars from Ust-Katav have been supplied to St. Petersburg, Lipetsk, Krasnoyarsk, Magnitogorsk, Krasnodar, Novokuznetsk. The income of UKVZ JSC at the end of 2021 amounted to 3.6 billion rubles (+87%), net loss – 308.5 million. UKVZ is part of the Roscosmos state corporation, the owner of the register of shareholders is VTB Registrar. There are no more recent data on the company’s financial results in open sources. Cars are delivered to different cities of the country. In the next part of our material we will show how cars are assembled. Modern trams are already commonplace. 74.RU team about the tram production process. She gives children excursions to the plant. We asked to complicate the program a little. At the plant, huge areas were allocated for the production of trams. We will walk with you through the main workshops Source: Natalya Laptsevich / 74.RU First, we will go to the workshop where the main components for future cars are loaded – rolled steel. It is supplied to the plant by various companies. The laser cuts the metal corner to the required length, and the process is controlled by an employee. Natalya Laptsevich / 74.RU Further down the road is a workshop, half of which is occupied by machines of unimaginable sizes. He brings metal parts to the parameters required by designers. In the “brains” of the machine there are hundreds of options for various parts of the moment of operation of a metal knife. To reduce the friction temperature, water is supplied to the part Source: Natalya Laptsevich/74.RU The next stage is welding in all its diversity. The task of welders is to firmly connect all the parts Source: Natalya Laptsevich/74.RUВ. next stage. , the outlines of the car are already visible Source: Natalya Laptsevich / 74.RU At the same time, the trams are assembled in another workshop. Here the weight of the parts is measured in tons, so they are moved by crane Source: Natalya Laptsevich. / 74.RU The frames are welded, processed, and the cars are sent to the glass section. A plastic case is formed. Once the fiberglass roof and cab exterior are complete, the vehicle is sent to the paint line. The final stage is in the assembly shop. At the time of our visit, trolleys for Lipetsk in the company’s black and blue color were being assembled on the conveyor. Source: Natalya Laptsevich / 74.RU Inside, workers are installing all the necessary equipment. “Segments” of wires hang from above Source: Natalya Laptsevich / 74.RU The entire process of assembling a car takes 90 days Source: Natalya Laptsevich / 74.RU On the car transporter, we noticed a part of the future carriage of an unusual color. UKVZ chief designer Oleg Slepov said that this is an integral part of the future three-section vehicle. Recently Kastor was tested in Chelyabinsk, and this is the next model. It will be used, among other things, for the production of light metro or metro tram cars – now a multi-section car with a two-cabin design is being prepared for production. Although it is not positioned primarily as a metro tram, it can be used on ordinary city roads,” says Oleg Slepov. – But at the same time, all the features are taken into account, all the richness that light metro cars should have, this is exactly what one of the future metro cars looks like in Chelyabinsk and, quite possibly, in other cities where. are preparing for the launch of such projects. Metro tram cars are longer than usual and have driver cabins on both sides Source: Natalya Laptsevich / 74.RU The estimated launch date for a new type of transport in Chelyabinsk is 2026 Source: Natalya Laptsevich / 74.RU All about the construction of the metro in Chelyabinsk – in the materials of 74.RU.

0 комментариев